One-Code-Per-Box Solution for Carton Production: Variable Inkjet Printing

As e-commerce and logistics continue to boom, carton packaging has evolved beyond its traditional role as a simple container. Today, businesses increasingly demand unique barcodes or QR codes on each carton to combat counterfeiting, prevent cross-shipping, and enable seamless product traceability. To meet these needs, manufacturers are turning to advanced variable inkjet printing technology—a game-changer for efficient, high-quality carton production. This article explores how the one-code-per-box approach works, its benefits, and why it’s becoming a must-have for modern packaging lines.

The Growing Need for Unique Carton Coding

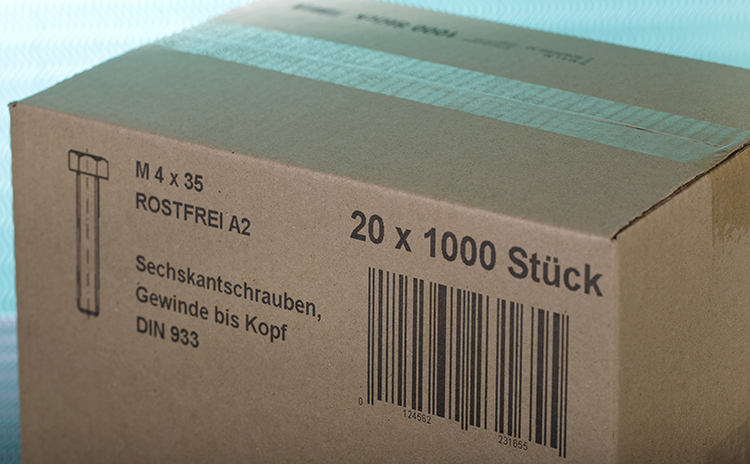

In the fast-paced world of online retail and global supply chains, ensuring product authenticity and traceability is more critical than ever. Counterfeit goods and unauthorized distribution can erode consumer trust and hurt a company’s bottom line. By printing a unique identifier—such as a barcode or QR code—on every carton, businesses can track products from production to delivery, verify their authenticity, and prevent mix-ups in the supply chain. This one-code-per-box strategy is especially vital for industries like pharmaceuticals, food and beverage, and consumer goods, where safety and compliance are non-negotiable.

How Variable Inkjet Printing Makes It Happen

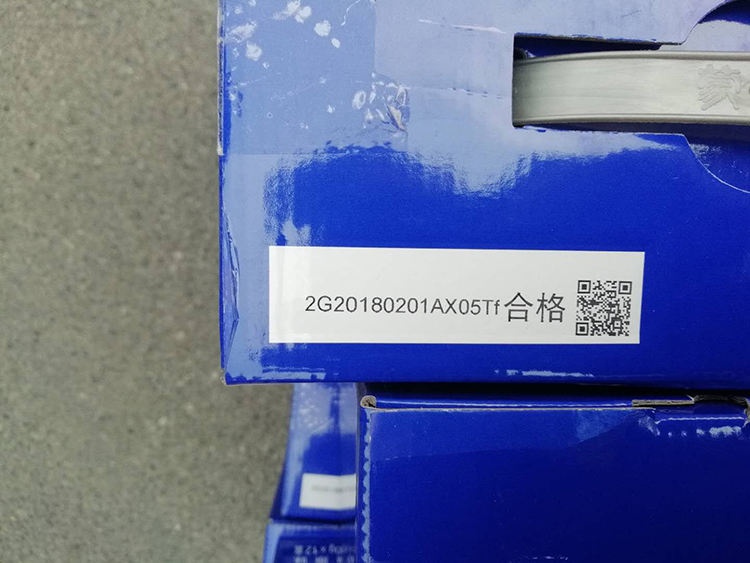

Achieving a one-code-per-box system requires specialized equipment and a streamlined production process. Variable inkjet printing technology, like that offered by companies such as Loogal, allows manufacturers to print dynamic, high-resolution codes directly onto cartons. Unlike traditional labeling, which involves applying adhesive stickers, this method prints unique data—such as batch numbers, expiration dates, or QR codes—directly onto the packaging surface.

Here’s how it works:

Specialized Printers: High-resolution inkjet printers, often powered by technologies like HP’s TIJ 2.5, can produce crisp, scannable codes at high speeds, even on moving production lines.

New Production Steps: To implement one-code-per-box, manufacturers add a coding station to their packaging line, where each carton is printed with its unique identifier in real time.

Versatile Applications: These printers can handle various data types, from simple barcodes to complex QR codes, and work with different carton materials, ensuring flexibility across industries.

This technology eliminates the need for pre-printed labels, reducing waste, cutting costs, and simplifying the production process.

Benefits of One-Code-Per-Box Printing

Adopting variable inkjet printing for one-code-per-box offers several advantages:

Enhanced Traceability: Unique codes make it easy to track products through the supply chain, ensuring compliance with regulations like the U.S. FDA’s Drug Supply Chain Security Act or China’s drug traceability requirements.

Anti-Counterfeiting: Individualized codes make it harder for counterfeiters to replicate products, protecting both brands and consumers.

Error Reduction: Direct printing minimizes mistakes associated with manual label application, such as misalignment or duplication.

Cost and Environmental Savings: By skipping labels, companies reduce material costs and waste, aligning with eco-friendly practices.

Real-Time Flexibility: Variable printing allows for on-the-fly data updates, enabling manufacturers to adapt quickly to changing needs, like updating batch numbers or adding promotional QR codes.

Why It’s a Smart Choice for the Future

As consumer expectations and regulatory demands grow, the one-code-per-box approach is becoming a standard in modern manufacturing. Variable inkjet printing not only meets these demands but also boosts efficiency and sustainability. For businesses looking to stay competitive, investing in this technology means better product security, streamlined operations, and a stronger brand reputation.

Whether you’re in e-commerce, food production, or pharmaceuticals, the shift to one-code-per-box printing is a practical step toward a smarter, more connected supply chain. With cutting-edge inkjet solutions, manufacturers can deliver packaging that’s as innovative as the products inside.