Loogal W108 inkjet printer supports horizontal and vertical printing for versatile application design, enables single or double-sided carton marking, and offers adjustable print heights of 3cm, 5cm, 7cm, or 10cm(extendable to 20cm via dual-printhead stitching) for large-scale projects. It delivers high-resolution, vibrant prints with crisp barcodes, graphics, and spot colors, significantly improving mark visibility and quality over existing market solutions while reducing costs through efficient direct-to-substrate printing.

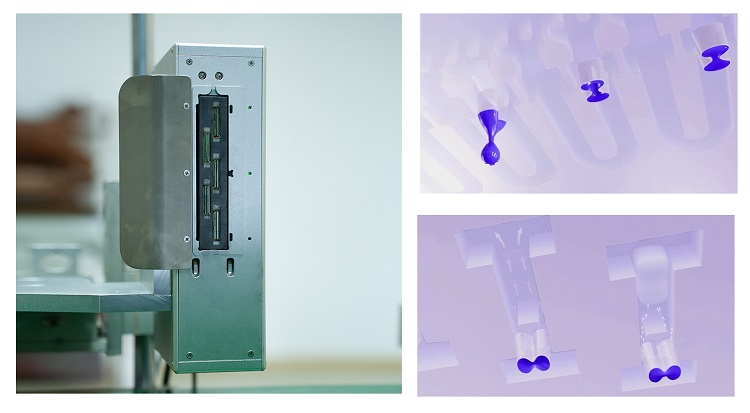

Get clean, crisp print every time, even when the printhead is left uncapped for 24 to 48 hours. Micro-recirculation technology to reduce pen servicing and resolve decap issues, without the need for a service station. Guarantees fresh ink at the nozzle for every print.

This solution delivers high-quality direct on-box marking at a fraction of pre-printed or labeled costs, featuring a 775ml backup ink tank for non-stop printing and easy printhead replacement to minimize downtime from errors, purge processes, or repairs.

Industrial wide-format printing redefines efficiency by enabling direct substrate marking (replacing labels), enhances sustainability via water-based/low-VOC inks and recyclable materials, and drives innovation in logistics, packaging, and manufacturing. Key solutions like Loogal's W108 (HP TIJ 4.0) and W110/W72 piezoelectric printers support high-speed, versatile applications while reducing waste and operational costs, aligning with Extended Producer Responsibility (EPR) regulations

In today’s fast-paced and strictly regulated supply chains, case coding is vital for driving efficiency, enabling traceability, and ensuring compliance. For manufacturers, distributors, and suppliers serving major retailers, choosing the right case coding solution is key to staying competitive.

The W108 wide-format inkjet printer utilizes HP TIJ 4.0 technology to achieve 1200 DPI resolution, ensuring sharp outputs. It supports vertical/horizontal printing, with a108mm single print height and 1–2 heads, eliminating stitching issues. Its printhead features a built-in micro-circulation system and automatic pressure adjustment, eliminating ink leaks and white lines. 775ml ink tanks reduce costs by 75%, aligning with HP’s maintenance-free design.

Horizontal or vertical printing capability provides design flexibility for a range of applications.And meanwhile, support for one or two sides of your carton printng. You can print in height of 3cm, 5cm,7cm and 10cm and even larger to 20cm when stitching two printheads, which provides significant cost savings and superior flexibility.

| W108 | |

|---|---|

| Print Height(mm) | W108-1 108mm*1; W108-2 108mm*2 |

| OS | LINUX |

| Print Speed | 20m/min @1200*600 dpi 40m/min @600*600 dpi |

| DPI | X direction: 200/300/400/600/1200dpi Y direction: 600/1200dpi |

| Print content | Text,date,counter,image,shift code,Julian date,1D&2D barcode,GS1,Database |

| Communication | Ethernet |

| Controller | 13.3"TouchScreen |

| Interface | USB/Sensor/Encoder/Alarm/Ethernet |

| Font | TrueType font |

| Ink Supply | 775ml Ink tank/Waterbased |

| Printable language | Simplified Chinese/Traditional Chinese/English/Spanish/Portuguese/Korean/Russian/Arabic |

| Upgrade | Firmware and software both can be updated by USB |

| Power | 120W /110-220VAC50/60Hz |

| Environment | Temperature5℃~35℃ Humidity10%~90% |

| Weight/Dimension | 16kg/37*35*14cm Controller:440*270*310mm Printhead:273*145*78.5mm |